|

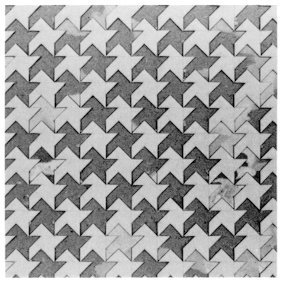

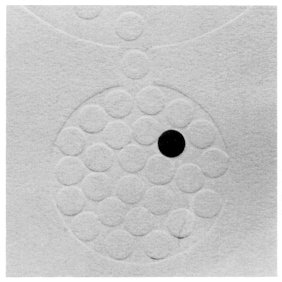

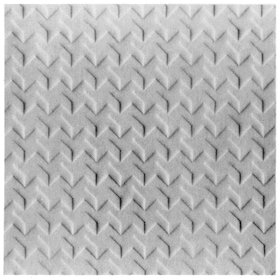

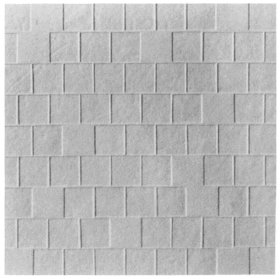

(iv) Embossing When the force for pressing becomes great in printing, it should be called pressing. This creates unevenness even if materials which are not as soft as thin paper are used. A change in the touch is created, and it also accompanies an optical effect as a shadow. There is a significant difference in feelings from a pattern drawn on a plane screen. Relief by embossing is very close to a plane pattern since only a small unevenness is generated. However, even if it is faint, the effect of swelling and sticking generates the three-dimensional effect visually or to the touch. Rather, the faint swelling creates delicacy, which is a large modeling effect. ·The work in Figure

626-b is an embossing by pressing using an old-fashioned type printing

machine. A large steel press plate is coming down to press. After water

was applied to a sheet of Bredan paper, it was put on the pattern in Figure

626-a made of ball paper. Then, a sheet of shock absorbing labor sheet

was placed on that, and it was pressed by a pressing board.

|