COST Action CA18203 – Optimising Design for Inspection (ODIN)

Author:

Dr Ivana Atanasovska, Department of Mechanics, Mathematical Institute SANU

Home page of the Cost Action CA18203

The Network website

COST Action CA18203 – Optimising Design for Inspection (ODIN) – 2019-2023 – has a goal to maximise the full benefit of in service, continuous monitoring of critical aerospace structures by integrating ultrasonic wave based non-destructive evaluation (NDE), energy harvesting and wireless sensor technologies at the design conception phase. Optimisation (of sensors and structures), computational modelling, advanced signal processing and advanced design approaches will be integrated to produce a novel framework, design tools and guidelines for the delivery of the first generation of self-sensing aircraft capable of delivering accurate structural prognosis.

Ultrasound based NDE techniques, energy harvesting and wireless sensor networks are being increasingly demonstrated to be effective in monitoring damage in aerospace components in laboratory setting. These components include critical elements such as airframe, engines, landing gear and control surfaces. However, there is an urgent need to integrate these approaches and techniques at the inception of an aircraft. This COST Action is bringing together the top European experts across these areas to support the development of an integrated framework for optimised self-sensing structures capable of diagnosis and prognosis, together with demonstrators and educational activities, including training programs, which will ultimately lead to cleaner and safer skies.

The primary aim of this COST Action is to advance Europe’s position of strength in aerospace through the development of intelligent structures integrated at the design inception phase through the creation of an interdisciplinary network of global researchers. This will be achieved through two primary missions; the synergising of the leading research in damage detection, energy harvesting, data processing, sensing and wireless technologies to create the most advanced autonomous damage detection system in the world (TRL 7-9) and to utilise the gained knowledge to develop standards/guidelines to optimise aerospace structures for Structural Health Monitoring (SHM) systems. This COST Action will bring together leading European experts across Mechanical and Electrical Engineering, Computer Science, Mathematics, Materials Science and Industry to support the development of an integrated framework for optimised self-sensing structures capable of diagnosis and prognosis.

This Action will maximise the full benefit of in service, continuous monitoring of critical aerospace structures delivering the first generation of self-sensing aircraft capable of accurate structural prognosis. This will improve maintenance strategies, increase asset availability, increase the use of advanced materials, reduce operating costs and ultimately deliver safer and greener air transport. A COST Action focused on the concept of Optimised Design for Inspection (ODIN) will allow the development of a breakthrough in scientific research and industry adoption. It will strengthen the EU aerospace industry. This Action will promote the mobility of leading Early Career Investigators (ECI’s) and established researchers in Europe with the aim of cross fertilisation. It will use COST Network tools that include workshops, a dedicated COST Action LinkedIn Group, meetings, dissemination activities and specialised conferences to deliver a step change in aerospace SHM. Short Term Scientific Missions (STSM) will focus on exchanges between internationally leading and emerging research groups in COST Inclusive Target Countries (ITC). The Action will aim to disseminate trans-European nationally or otherwise funded research activities in this area to a greater audience, increasing its impact. This Action will develop a consolidated network of interdisciplinary researchers (ECI’s and PhD) for training and mentoring, maximising their potential. This network is of paramount importance for three reasons: (1) the identified disciplines represent unique skill sets and without this Action it will be impossible to integrate all the individual aspects effectively and efficiently (2) there is no common agreed upon standard or guideline for testing the individual aspects with many researchers demonstrating significantly different outputs for the same off-the-shelf device (3) there needs to be a connection between academia and industry to ensure developments can be transferred out of the laboratory. At this moment, 28 Countries participate in this COST Action, with high Gender Balance in the Management and Research structures.

Serbia is represented by two research teams: a team from the Mathematical Institute of the Serbian Academy of Sciences and Arts and a team from the Faculty of Mechanical Engineering, University of Belgrade. Both of the teams are involved in the activities of the Working Group 1 (Design, Optimisation and Integration), led by Prof Chiara Bisagni, Delft University of Technology, Faculty of Aerospace Engineering, Netherlands.

Working Group (WG) 1: Design, Optimisation and Integration

This group encompasses industrial aerospace design engineers and experts, mathematicians, computer scientists and optimisers with the objective to analyse the requirements for integrating SHM systems at the inception of an aerospace design. A significant challenge for this group is to ensure that specific aerospace requirements are communicated effectively and efficiently to the SHM system designers.

Four main tasks are defined in this WG delivering definitions of working environment and geometric constraints and required information to feed into maintenance and safety management protocols:

T1.1: Increase industry participation through promotion and dissemination at trade shows, utilising existing participant contacts and the establishment of a social network ODIN group;

T1.2: Establish design criteria, based on industry requirements for a representative wing structure element. This will include geometry, loading, temperature etc. These criteria will be disseminated widely to increase network/WG1 participation. The data can then be used as the starting point, at first, for optimisation due to loading and subsequently for an SHM system;

T1.3: Development of optimisation strategies and guidelines for systems and structures and design of demonstrator wing section;

T1.4: Dissemination of work group findings, including industry guidelines through conference, trade shows, workshops and industrial seminars.

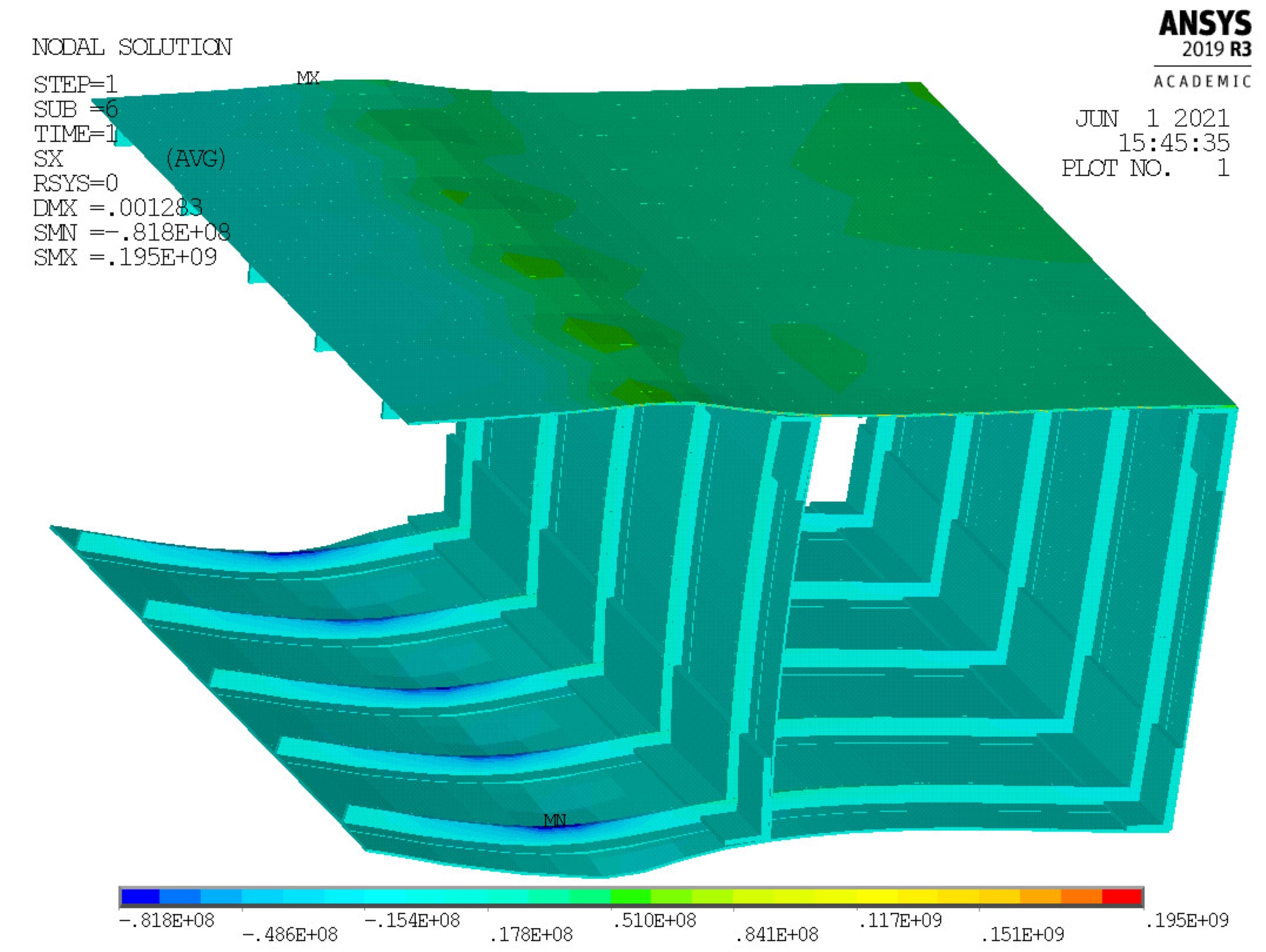

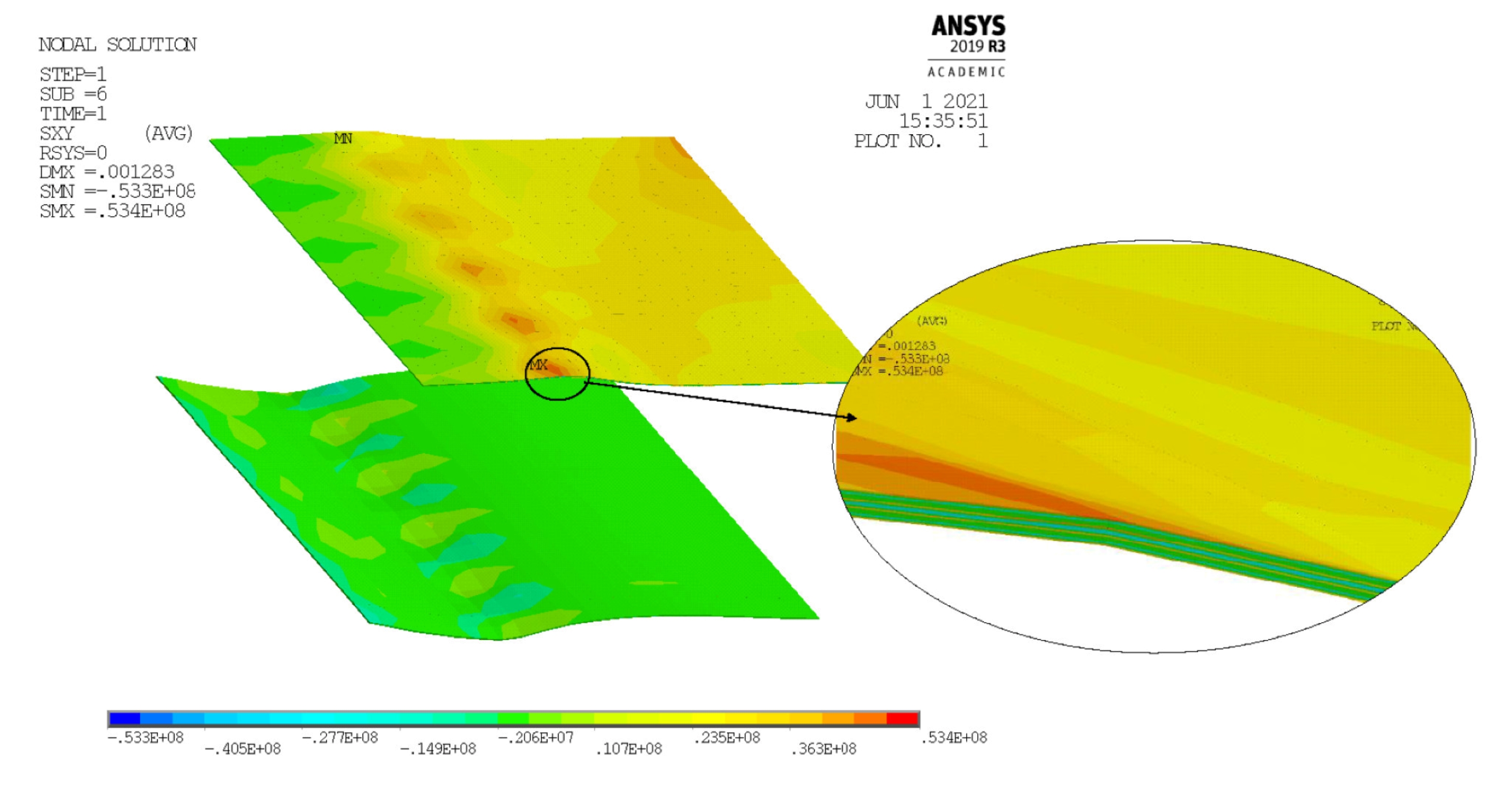

The research group from the Mathematical Institute of the Serbian Academy of Sciences and Arts, led by Dr Ivana Atanasovska as Management Committee Member, is very actively involved in the analysis of the representative wing structure element. The analysis is performed using Software for Finite Element Analysis – ANSYS 2019 R3 Academic Research Mechanical.

Gallery

Second ODIN Management Committee Meeting, Athens, February 2020

(Courtesy of Ivana Atanasovska)

Normal tensile stresses at the representative wing structure - Contour plot of deformed structure magnified 30x

(Unpublished research results of Ivana Atanasovska and Milica Milić)

Shear stresses at the wing structure’s composite plates -

Contour plot of deformed structure magnified 30x and zoomed detail displays stresses by material layers

(Unpublished research results of Ivana Atanasovska and Milica Milić)